Nov

Are you wasting warehouse money and space? Why Cantilever Racking Systems Could Be the Answer

- 2025

- Becky

Go into most warehouses and you’ll see it filled with adjustable pallet racking. It could be used in a 4PL business to store large pallets or a builder’s merchant yard stocking large bags of cement. While a lot of the products you store in your warehouse fit perfectly on your pallet racking, what happens when you have oversized items that don’t fit within the shelf space?

In our blog, we take a long at how cantilever racking systems could be the ideal choice when pallet racking doesn’t quite suit the stock. We look at how these systems maximise the space, reduce costs in your warehouse and the different configurations to choose from.

Why do you need cantilever racking?

You see it all the time – long pipes balanced on pallet racking, timber leaning against walls, heavy items in piles on the floor or oversized stock incorrectly stored on pallet racking?

Not an ideal situation. First of all, by choosing an inefficient storage option you’re not making the use of your valuable warehouse space. Then there’s the fact that by storing items incorrectly, you increase the risk items getting damaged. Last, and perhaps most importantly, it might be risking the safety of your employees.

Cantilever racking offers the ideal solution due to its configuration. The problem with pallet racking is the restrictions you’re faced with due to the size of the shelving. While long items can be fed through the end of the racking bay, this approach will slow down speed of retrieval. Cantilever racking is different because it has an open-fronted design that allows you to load items over the arms.

What is difference between cantilever racks and pallet racks?

To fully understand the advantages of cantilever racking, you need to compare the structure to the traditional pallet racks.

A pallet racking structure consists of four vertical frames (uprights) connected by beams that span the uprights. These beams sit at the front and the back of the structure with braces added to create additional structural strength. The end result are cuboid shelf spaces on which you store the products. The problem with this configuration is that you have limitation on the size of the shelving cuboid.

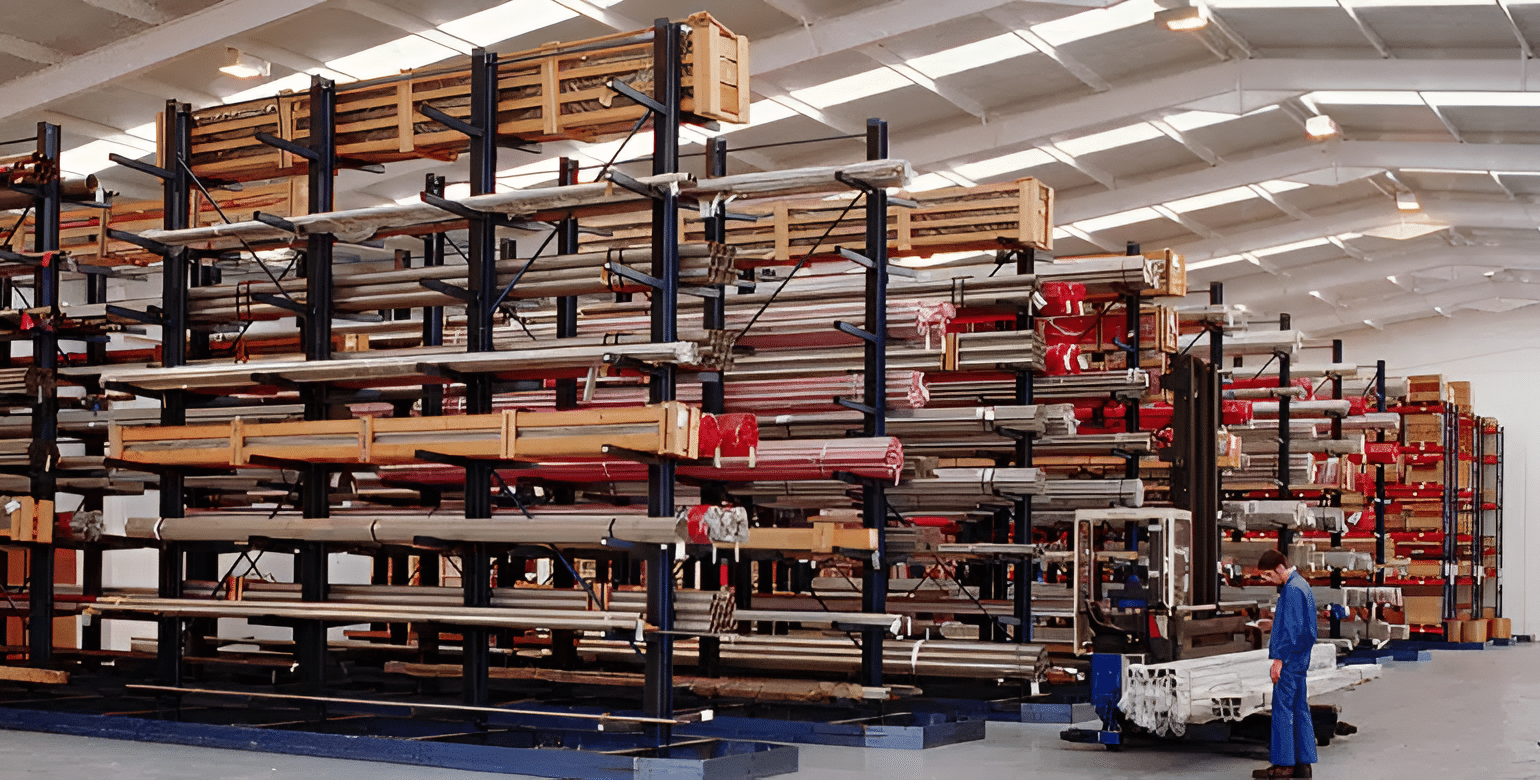

Cantilever racking is different because it uses a single row of vertical upright columns, fixed into a sturdy base structure that are positioned horizontally and extend out on the ground. X-shaped braces are fixed between the upright columns to keep the structure in position. Rows of horizontal arms are connected to the uprights which you adjust to different heights depending on the product weights and dimensions. Stock is stored by lying the items across the arms.

There are two different configurations to choose from:

- Single-Sided Cantilever Rack:

Cantilever arms are fixed to one side of the cantilever column with the structure typically sitting against a wall. You’ll commonly see them used in builders’ merchants and DIY retail back-of-shop settings where they’re placed around the perimeter.

- Double-Sided Cantilever Rack:

Cantilever arms sit on both sides of the column to provide twice the loading capacity allowing you to hold materials on either side of the racking face. You’ll frequently find them located in warehouse aisles and industrial yards carrying loads such as steel and pipes. In larger DIY warehouses and builders’ merchants.

How to reduce costs with cantilever racking

Now you know all about cantilever racking, the next thing to consider it whether it can save money for your warehouse or builder’s yard.

Are you struggling for storage space?

One of the problems when storage heavy and oversized items, is the amount of valuable space they can take up in your warehouse. Now you have a decision to make – do you move to larger premises or reduce the amount of stock you hold. Cantilever racking offers multiple advantages. Not only is it ideally suited to hold outsized stock but the structure has a very slim profile that will only take up a small amount of space in your warehouse. Thanks to its robust structure, the racking can be built up to 10 metres high, with arms positioned at regular intervals to support a wide range of goods. This design allows you to store your heavy stock vertically while also maximising the height in your warehouse. Even better, go for a single-sided option and you can build it against a wall or use a double-sided system for double the storage capacity within a very small area.

Are you experiencing stock wastage through damage?

When you’re balancing tight warehouse budgets, the last thing you want to do is waste costs through stock wastage. The problem is, when storing long, cumbersome items it is incredibly important to keep them level. This is certainly the case for items such as timber planks, pipes or mouldings which, if they aren’t laid flat, will simply warp or split. Due to the flexibility of cantilever you can adjust the arms exactly to meet the profile of your stock allows for storage suited to the profile of your stock. There is another benefit to a cantilever structure. The open form of the structure improves airflow and drainage which makes it ideal for products such as timber which need to avoid extended periods of dampness.

Are you wasting time to slow picking methods?

When working in a busy merchant’s yard, time is money. Products need to be easy to spot by your customers – after all you don’t want to miss a sale because they can’t find the product they’re looking for. Next, you need to get their order picked and ready to ship without delays. Cantilever racking has an open-fronted design which means there is no obstruction between the bays, providing full visibility of the stock and direct access for the forklift trucks. It can also help reduce the amount of time spent on stock inventory!

Are you struggling with frequently changing stock profiles?

In most warehouses or builders merchant yards, you’ll find your storage requirements will change depending on customer demand for products. One month it might be large bags of cement, the next timber panels are in demand. The good news is, your cantilever racking is flexible and can adjust quickly and easily without significant modifications to the structure. This is all down to the adjustable arms which can be set at varying heights to ensure the width and lengths of the load is fully supported. All you need to do is quickly and easily unclip the arms and fixing them on the new position.

Are you wasting costs due to accidents?

The problem when storing long or oversize products is the tendency to stack them incorrectly – whether that’s vertically or allowing items to overhang off the shelf. This raises serious safety concerns with it only taking a member of public to pick a single unit and the entire stack comes crashing down. With cantilever structures, the arms on the racking provide a steady frame that support at intervals along the length of the item. Retaining pins can be fixed to the end of the arms to prevent items from falling over the end of the arm – ideal for stock such as pipes which can roll or slide. You also have the option to place decking over the arms which makes it ideal when storing items that may vary in length and size that might fall through the gaps in between the arms.

Cantilever racking from Teepee

At Teepee, we can design a tailor solution that exactly meets the needs of your warehouse or yard. We will ensure your cantilever racking suits the requirements of your business to maximise productivity, capacity while keeping your employees and customers safe. Need something a little bit extra? Did you know we also design and supply a range of storage solutions included pallet racking, wide-aisle racking, industrial shelving and mezzanine floors. This wide range of products means we can provide you with a storage solution that works perfectly for your business.

Cantilever Racking FAQ

- What is cantilever racking used for?

Cantilever racking is designed to store long, bulky, or irregularly shaped items such as timber, pipes, steel bars, furniture, and sheet materials. Its open-front design allows easy access without vertical obstructions.

- Does cantilever racking need specialised equipment to pick stock?

One of the great advantages of cantilever racking is that it expands your storage options but doesn’t necessarily require specialised equipment with standard forklift trucks working seamlessly with the structure. However, if you were looking to maximise your storage capacity there is the option to reduce the spacing between the runs of cantilever racking. In this case you would need side loaders or multi-directional forklifts which can work within the narrow aisle space.

- Can you use cantilever racking outside?

Cantilever racking is a fully flexible system which can be used both inside the warehouse and, when a galvanised coating is applied, outside in the yard. This makes it the perfect choice for builder’s merchants, garden centres or warehouse yards. The robust structure can withstand almost every weather condition, and the galvanised coating minimises the risk of corrosion. You also have the option to choose a roofed cantilever structure which will product products stored on the racking.

- Can cantilever racking hold heavy loads?

Yes, cantilever racking is engineered to support substantial weight although how much it can hold depends on the design and the materials used. Cantilever arms can be designed for either light-duty or heavy-duty applications, potentially supporting up to 2500kg per arm. The system should always be customised exactly for your requirements and inventory.

- Is cantilever racking suitable for mixed inventory?

Yes. While ideal for long items, cantilever racking can also be fitted with shelves or mesh decks to hold smaller goods, making it versatile for mixed-use environments.